14

PRINT.IT

01732 759725

COVER STORY

Enterprise print centres face

many of the same challenges as

commercial print service providers

(PSPs), including the need to

diversify their print offering and

provide value for money.

Pressure on managers to run

in-house print rooms on a more

commercial basis raises many

questions: Are there new services

that I could realistically offer internal

print customers? Are there jobs I

currently outsource that I can bring

in-house? Are there opportunities

to extend my services to customers

outside the business? What

investment do I need to compete

with outside providers? What impact

will my choices have on broader

corporate commitments to cut costs

or reduce carbon emissions?

These are the sorts of questions

that PSPs have grappled with for

years. For many, the answer has

EFI H1625 At a Glance

n

Entry-level to mid-level wide format printer

n

LED ‘cool cure’ inkjet technology

n

Hybrid roll-to-roll & flatbed printing

n

Fast change-over from rigid to roll-fed materials

n

Wide range of media supported thanks to top

temperature of 40 °C

n

Prints direct onto boards up to 3m in length

n

Four colour inks (CMYK) and two white channels as

standard

n

Resolution of up to 1200 x 600dpi

n

Eight levels of variable drop greyscale for high quality

gradients and solid colours

n

Variable print speed, from 7.4 m

2

/hour in Ultra-

Quality Mode (1200 x 600dpi) to 42 m

2

/hour in

Express Mode (300 x 300dpi)

n

Energy-efficient

n

Supplied with EFI Fiery XF Digital Front End (DFE) for

fast, accurate job processing

been to diversify into wide-format

printing, such as billboards, signage,

posters, banners, wallpaper and

window film.

More than half the 1,200

print professionals surveyed by

Infotrends for the 2015 FESPA Print

Census expressed an interest in

buying digital wide format printing

equipment. Of these, almost one in

two (45%) said the investment would

enable them to enter new markets

with new services.

UV inkjet

There are many wide format printing

technologies to choose from, but the

most popular, according to the FESPA

Print Census, is UV printing. It was

the technology of choice for 27% of

respondents, ahead of textile printers

(21%), solvent printers (17%), eco

solvent printers (16%) and latex

printers (14%).

The fastest growing segment

of the overall UV printing market

is UV inkjet printing. In its report

The Future of UV Inkjet Printing to

2018

, Smiths PIRA states that the

market for UV inkjet-printed products

increased from $3.9 billion in 2007

to $6.7 billion in 2012, and is set to

grow even more strongly to $15.9

billion by 2018.

The distinct qualities of UV

inkjet, notably durable, weather-

proof, lightfast output, have made

it particularly suitable for outdoor

advertising, and this will remain

the dominant application. However,

as the market expands and new

applications are developed, Smiths

PIRA expects advertising’s share of

the total volume to decline.

LED ‘cool cure’

EFI is a major player in the UV inkjet

market. It provides a wide range

of UV inkjet printers based on LED

‘cool cure’ technology, and has so

far installed more than 500 units

worldwide.

One of the big benefits of UV

inkjet is that it virtually eliminates

VOC emissions by rapidly fixing ink

before evaporation can occur. This

creates a more comfortable working

environment for employees and

removes the need to set up printers

in specially ventilated areas.

Traditionally, UV curing has been

achieved through the use of mercury

vapour lamps. EFI UV wide format

printers use energy-efficient LED

lamps instead.

Cool cure LED technology has a

number of advantages over mercury

lamps. These include:

n

Significantly lower power

consumption. According to analysis

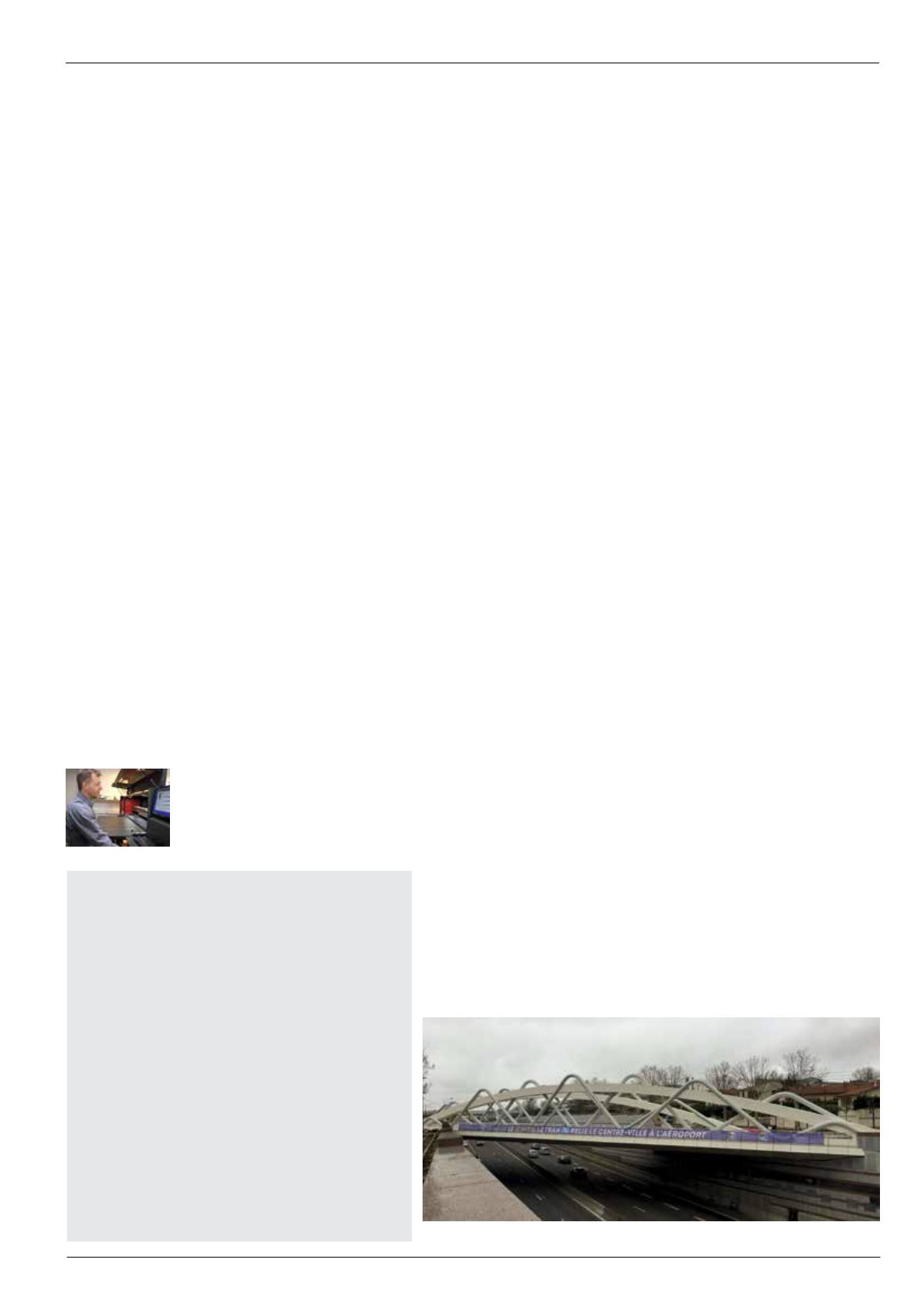

EFI’s hybrid wide format printers give print centres the flexibility to

bring more jobs in-house and develop new service offerings

Widening

your horizons

Walding Printers,

Linz, Austria

Broader appeal: Evolution Graphique