Consumer adoption of 3D

printing is unlikely to happen

in the next 5-10 years and 3D

printing in the classroom and

macro 3D printing of large

structures are more than 10

years away, Gartner claims in

a new report,

Hype Cycle for

3D Printing, 2014

.

Pete Basiliere, research vice

president at Gartner, argues

that until prices come down

and ease of use improves, 3D

printing is likely to be dominated

by business and medical

applications.

He said: “Hype around home

use obfuscates the reality

that 3D printing involves a

complex ecosystem of software,

hardware and materials whose

use is not as simple as ‘hitting

print’ on a paper printer.”

Some business applications

are already widely used, notably

prototyping, and over the next

two to five years, Basiliere

expects there to be greater

adoption of 3D printing in

enterprises driven by growing

use of 3D print creation

software, 3D scanners and 3D

printing service bureaux.

“At around this time, 3D

printing of medical devices

will offer exciting, life-altering

benefits that will result in global

use of 3D printing technology

for prosthetics and implants,”

Basiliere said.

New bioplastic set

to accelerate 3D

printing market

Biome Bioplastics, a UK

developer of plastics made

from plant starches, has

launched a new material for

the 3D printing industry that

combines the benefits of

plant-based plastics and oil-

based filaments.

Plant-based plastics are

already a popular choice for 3D

printing because they are easier

to work with during processing

and are food-safe and odour-

free. However, oil-based printing

filaments are still used because

they have a higher softening

point and make more flexible

models that will bend before

they break.

Biome Bioplastics says

that compared to existing

alternatives, Biome3D,

developed in partnership with

3Dom Filaments, offers a

superior finish and flexibility,

with ease of processing and

excellent printed detail. It also

runs at much higher print

speeds, reducing job times.

End-to-end 3D printing

Dell has added three award-winning MakerBot Replicator 3D

Printers to its portfolio of 3D design solutions. When combined with

Dell Precision workstations, they provide an end-to-end 3D digital

prototyping solution for small and medium-sized businesses.

Prices start at £999 ex VAT.

Digital maturity just

five years away

Seven out of 10 business

leaders are confident they

can transition from a state

of digital transformation to

digital maturity within just

five years, according to

research commissioned by

Ricoh Europe.

Digital maturity – where an

organisation uses sophisticated

tools to drive performance

and demonstrates an on-

going commitment to digitally

managed processes – is now a

priority for 77% of businesses in

Europe and the Middle East.

The main obstacle to digital

maturity is cost (cited by 68% of

respondents). However, business

leaders recognise that there are

financial benefits in making the

transition, with 73% saying that

achieving digital maturity will

lead to an increase in profits.

Other benefits include faster

business processes (80%),

improved competitiveness

(70%) and faster decision-

making (69%).

/

thoughtleadership

Virgin Holidays

saves paper with

digital signatures

Virgin Holidays has achieved

significant cost savings

and efficiency gains since

implementing a digital

signature solution in its

Human Resources (HR) and

Procurement departments.

The long haul transatlantic

tour operator is using the

DocuSign Digital Transaction

Management (DTM) platform

to digitise the signing of

contracts with suppliers

and new employees and for

the centralised storage and

management of contracts.

Implementing digital

processes has speeded up

the signing of contracts,

reduced paper consumption

and improved record-keeping.

The HR department alone has

eliminated material costs of

around £10,000 per year and

PRINT.IT

7

n

An inevitable consequence

of digital transformation is a

reduction in printing and paper.

The Environment Agency, for

example, is hoping to prevent

the printing of 23 million paper

waste transfer notes (WTNs)

annually by introducing an

electronic system that lets

organisations create, share

and store WTNs online. Other

benefits of the free Electronic

Duty of Care (eDoc) system are

reduced filing requirements,

faster data retrieval and

improved data tracking,

auditing and reporting.

/

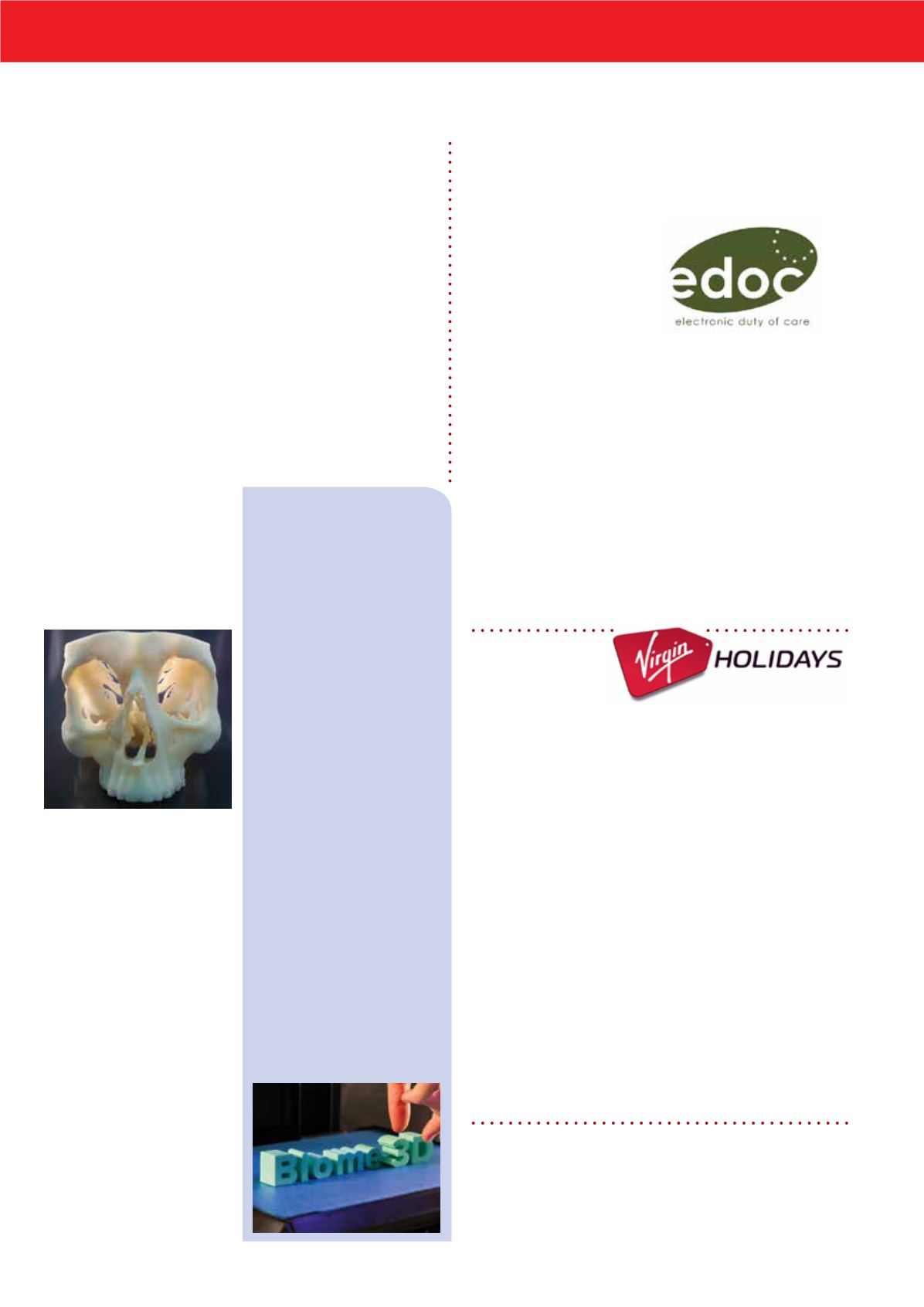

A good example of 3D printing

in medicine is Replica 3DM’s

use of Stratasys 3D Printers

to convert patient CT scans

into 3D models that are used

as surgical guides to identify

correct procedures and test

implants for size and fit before

surgery. The medical 3D printing

specialist is already using the

technology in 12 NHS hospitals,

significantly reducing surgery

time, theatre costs and the

time patients spend under

anaesthetic. Matthew Sherry,

MD of Replica 3DM, said: “A

3D model equips surgeons with

a hands-on perspective which

cannot be achieved by looking

at a computer screen. They

can easily rotate, inspect and

analyse each surgical procedure

on a case-by-case basis,

enabling them to pre-bend

implants knowing that they will

fit the patient perfectly.”

3D printing growth to come

from medical applications

cut signing time for customers

and employees from two weeks

to 48 hours.

The Purchasing department,

too, has made efficiency gains. It

has cut the time taken to process

purchasing contracts internally

from two hours to less than

10 minutes and reduced time

spent tracking, filing and finding

documents as the DocuSign DTM

centralises the filing of contracts

previously kept in numerous

locations and formats.

Because it is so much

quicker to arrange a

procurement agreement using

DocuSign than a paper-based

system, staff are now more

inclined to go through the

purchasing department, bringing

much needed visibility to the

process. Over the last year,

Virgin Holidays has seen a 100%

increase in recorded contracts.